Cornell-Led Team Uses Sunlight, Seawater to Make Low-Cost Green Hydrogen

Cornell researchers unveil solar device that turns seawater into affordable green hydrogen and clean drinking water.

A Cornell University-led research team has developed a solar-powered device that produces low-cost, carbon-free hydrogen directly from seawater — and generates potable water as a byproduct — marking a potentially transformative step toward clean energy and water sustainability.

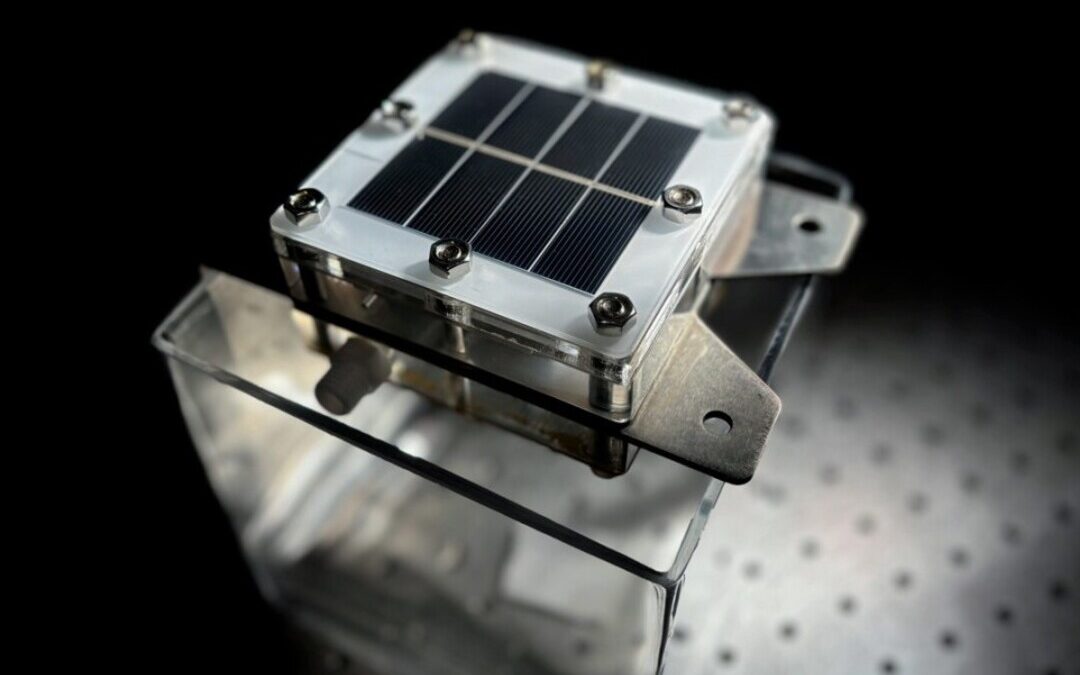

A study published Tuesday in Energy and Environmental Science details the hybrid solar distillation-water electrolysis, or HSD-WE, system. It uses sunlight to simultaneously desalinate seawater and split water molecules into hydrogen and oxygen.

The prototype, which operates under natural sunlight, produces up to 200 milliliters of hydrogen per hour with an energy efficiency of 12.6 percent.

Researchers estimate the new technology could reduce the cost of green hydrogen production from its current average of $10 per kilogram to just $1 per kg within 15 years — a key milestone in achieving global net-zero emissions targets by 2050.

Tackling the water-energy bottleneck

“Water and energy are both critically needed for our everyday life,” said Lenan Zhang, assistant professor of mechanical and aerospace engineering at Cornell and lead author of the study.

“But typically, if you want to produce more energy, you have to consume more water. Our approach solves both challenges at once.”

Green hydrogen, typically produced using electrolysis of high-purity deionized water, remains cost-prohibitive due to the significant water purification requirements.

Zhang’s team sought to circumvent that issue by using two of Earth’s most abundant and free resources: solar energy and seawater.

Making the most of solar energy

The device, measuring 10 by 10 centimeters, captures electricity and waste heat from photovoltaic cells.

While most PV cells convert only about 30 percent of solar energy into electricity, the remaining heat in this system is recycled to power a thermal desalination process.

“Short-wavelength sunlight generates electricity, while longer-wavelength light becomes heat for distillation,” Zhang said. “This way, all the solar energy can be fully used. Nothing is wasted.”

A key innovation is using a capillary wick, which traps seawater in a thin film in direct contact with the solar panel.

This design enables rapid evaporation using minimal energy, achieving over 90 percent thermal efficiency.

The resulting vapor is condensed into clean water and routed through an electrolyzer to produce hydrogen.

Collaboration and future applications

The project brings together researchers from Cornell, MIT, Johns Hopkins University, and Michigan State University. The study’s lead author is Xuanjie Wang of Lehigh University.

Other co-authors include doctoral student Yipu Wang, postdoctoral researcher Jintong Gao, Yayuan Liu of Johns Hopkins, and Xinyue Liu of Michigan State.

The project, funded by the National Science Foundation, builds on Zhang’s earlier desalination work at MIT, which was named one of Time magazine’s “Best Inventions of 2023.”

Beyond reducing costs, Zhang sees the potential for the technology to be integrated into solar farms, which could also cool PV panels, increasing their efficiency and lifespan.

“We want to avoid carbon emissions and pollution,” he said. “But cost matters, too. The lower the cost, the greater the potential for widespread adoption.”